In screen printing on apparel, there are various techniques and two types of inks that are commonly used, water-based inks and Plastisol inks. So, which one is the best? Well, like many techniques in this field, it depends. In this post, we will compare the two and ultimately give you advice on the best ink for the type of print you are trying to achieve.

What is water-based ink?

Water-based inks are inks made with water instead of plastic or PVC, water-based inks can be split into two primary ingredients which are water and pigment. One of the main features of this type of ink is the fact that it is a more eco-friendly option. Water-based inks soak into the fabric as opposed to sitting on top of the fabric, therefore, making the print smoother and breathable. Water-based inks are better when printing on light-colored cotton, if the design has a lot of details, and if the ideal print has muted colors.

What is plastisol ink?

Plastisol ink is made up PVC particles suspended in a liquid plasticizer, it is very durable, flexible, and is commonly used in apparel printing. Plastisol is thick and opaque and it can be mixed easily to create just about any color imaginable. With plastisol ink, we can create special effects like suede, glow-in-the-dark, glitter, shimmer, or metallic. Plastisol is most commonly used on dark-colored fabrics, and it is ideal when printing designs that are less detailed and very colorful.

Which one is the best?

The best ink depends on what type of print, the fabric, and the design you are trying to accomplish as there as many factors to consider. Below we’ve broken-down the considerations for you to make your choice as well as our opinion.

Softness & Breathability

Water-based inks allow for a lighter and softer print which makes the fabric more breathable and comfortable, while Plastisol tends to be a lot thicker and because it is made up of PVC (or plastic) particles, and the ink sits on top of the fabric, it is less breathable around the printed area.

Color

Plastisol inks allow for more vibrant colors and a more accurate color matching process, especially on darker colored fabrics. Vibrant prints using water-based inks are possible, however, the fabric would need to be a lighter color. Plastisol is considered 100% solid, so every bit of it stays on the fabric when cured.

Durability

While both types of inks are durable, Plastisol ink has the reputation to be the most durable, however, some factors need to be taken into consideration. For example, Plastisol ink is thick and can withstand several washes before fading, although, Plastisol inks tend to crack when exposed to high heat. Water-based inks tend to fade faster with frequent washing.

Versatility

With Plastisol inks, you are able to use a variety of different types of fabrics, other inks, and additives. Water-based ink is best suited for 100% cotton fabrics. Blended textiles are less likely to absorb the water-based ink, although there are some tricks to do this successfully, you will run into a lot of difficulties.

Eco-friendliness

While water-based inks are more eco-friendly, but it’s not by much. Why? Well, water-based inks also contain plastic in the form of acrylics and other binders. they rely on solvents that evaporate, leaving the pigmented binder compounds on the garments. The primary solvent is water, but they often contain co-solvents such as formaldehyde and alcohol. These solvents can be harmful and put you at risk unless you use protective gear to protect you from evaporative fumes. Therefore, the two inks are not that much different when it comes to this issue.

Cost

In most cases, plastisol inks tend to have a lower cost. However, as more people prefer softer prints, water-based inks are becoming more popular and print shops are able to reduce their cost by making large purchases with ink vendors. Therefore, consumer prices may vary from shop to shop.

Based on the criteria above, we believe plastisol inks are ultimately the best option in most cases. It is easier to use, cost-effective, and long-lasting ink. Plastisol is sure to maintain the color and details of the design for a long time.

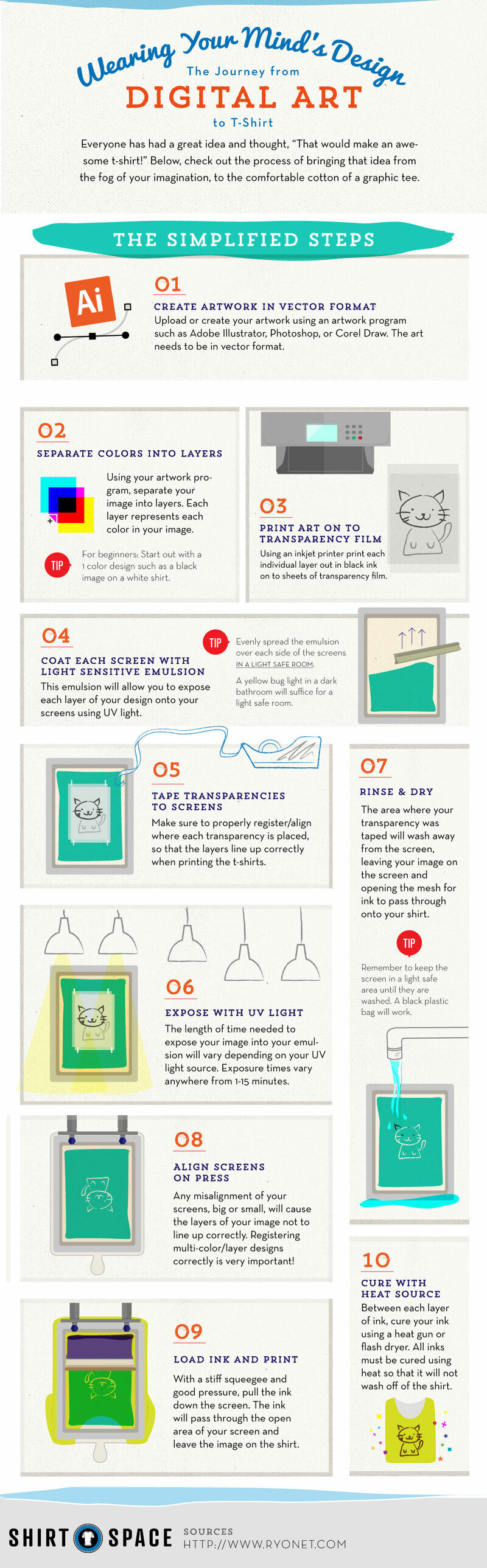

Check out T-Shirt Screen Printing Instructions

For questions, send us an e-mail at quotes@familyindustriesla.com, or give us a call at 323.227.1547 and we'd be happy to help.

If you’d like a quote, contact us!

Our showroom at 2755 Fruitdale Street, Los Angeles, CA 90039 is open by appointment only from 10 am - 4 pm Monday through Friday.

Author: Irene Floridia - Content Creator