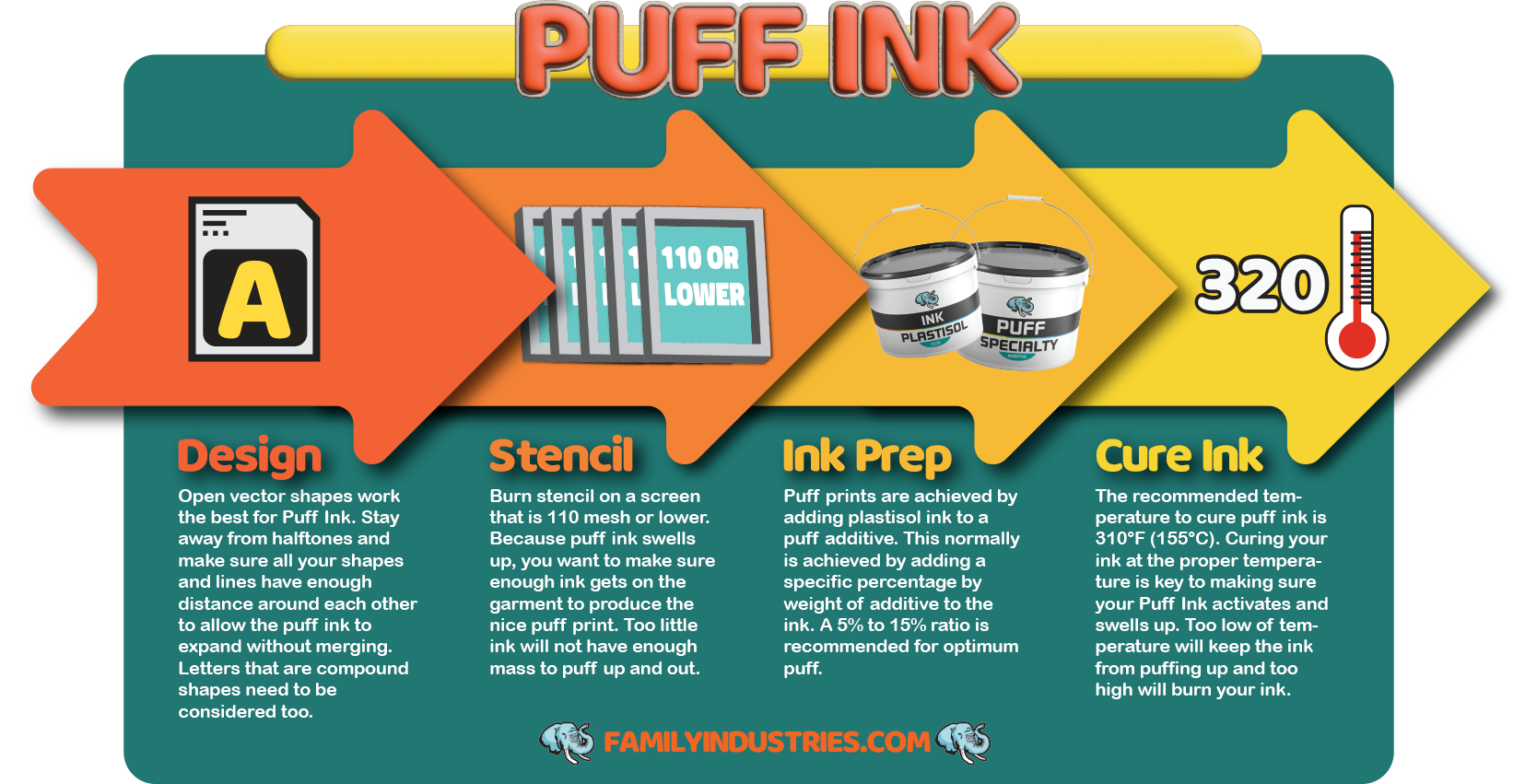

Screen printing might sound like it’s a straightforward process but there are many print effects that can be achieved with the right technique. The different screen printing methods are used to create a specific look to fit with the style you’re looking for. In order to achieve certain looks, you may need to adjust your artwork file or overall design. Don’t worry, we will take you through those steps!

In this guide, you will find the best T-shirt printing methods explained, exploring how each method works, the process, and the end results. Each of these methods are widely used by screen print shops around the world.

About Screen Printing

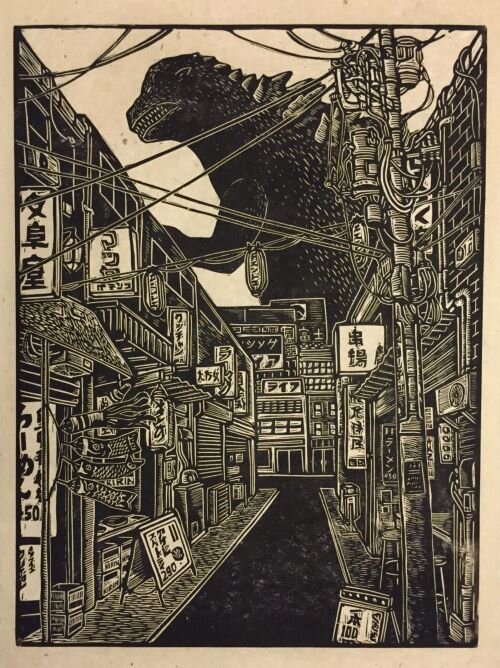

Screen printing is one of the most popular, established, and widely used amongst print shops. The process involves using screens to apply ink to apparel and other various materials. Also known as silkscreen printing, screen printing is a versatile and effective printing method that allows you to produce T-shirts with outstanding quality and a tactile feel. And, because the inks are absorbed deeply into the fabric, it is possible to achieve vivid, bright colors and maximum durability.

This is one of the most traditional methods of T-shirt printing, with experts believing it dates back as far as ancient China. However, it became popular in the 20th century, when Andy Warhol used the technique to create his iconic Marilyn Monroe portrait. It has since been used to create flatstock such as band posters, art prints, and graphic tees.

What Is The Screen Printing Process?

Design Creation

Screenprint designs are often done using various software such as illustrator. You will want to ensure your file is in the right format before you begin creating your design. Size is very important and you will want to ensure the file can be re-sized according to the print surface.

File Formatting

Vector files are needed to create a perfect print. Vector files are mathematical calculations that create lines and figures on our monitors. Unlike working with pixels, you can expand or minimize these vectors as much as you want, without impacting the quality. As well as being saved as a vector, the artwork must also be separated, with each color on a different layer. This is because, in the screen printing process, each tone is printed using a different screen.

Screen Preparation

The screen needs to be coated with a photosensitive emulsion. This creates the green background you might have seen on a screen printing screen. This is a simple process but must be done carefully to ensure that the liquid is distributed evenly.

For the photosensitive emulsion to work properly, it must be left to dry in a cool, darkroom. If the emulsion is exposed to light at the wrong time, it could jeopardize the full process.

Stencil Creation

Once the screen is dry, the design is placed on top of it and secured in place using an adhesive. The screen is then placed under a strong source of UV light. The parts of the screen that haven’t been covered with the design will harden, while the rest will remain soft. In effect, the design has now been burned into the emulsion. When the screen is fully dry, the design can be removed using a small brush and water. A negative component of the artwork will be left and the artwork is ready to be printed using the preferred ink and technique to achieve the right look.

Color Separation

If your design features more than one color, the process is repeated so that each color in your design is separated into individual layers on different screens. So, if your design has two colors, you’ll need two screens.

Application

Now that the screen is ready, it’s time to start the actual printing. The T-shirt will be placed in the screen printing machine, with the screen carefully placed on top. The ink will then be placed on top of the screen and evenly distributed across the surface using a squeegee.

Learn more about the life of a screen from The Metropolitan Museum of Art

What Are The Different Types of Screen Printing?

With screen printing, you can create different finishes such as crackle or glow in the dark, but there are also different techniques that can be done to create a specific look for your print. These different techniques are used when you have a specific look in mind or you’re looking for a specific or unique aesthetic.

Spot Color Screen Printing

Spot Color Screen Printing is the most common t-shirt printing method. It uses the stock color of the ink by printing it through the stencil of the screen. It produces a vibrant solid spot of color and creates a thicker layer of ink depending on the ink and mesh count used.

Being it is one of the most beneficial in printing darker garments. It is useful for printing 1 – 4 colors; when you have more spot colors, other printing methods such as the simulated process may be a good option.

Because spot colors layer an infinite amount of colors, they can provide a much more vibrant and detailed print. In addition to the variety of options, spot colors provide much better consistency from print to print. When printing a solid color with process inks, there may be slight variations in the color balance that can affect the color’s consistency. While spot colors may cost a bit more, they can add a lot to your project making the extra cost well worth it in the end. Check “How To Screen Print: Spot Color”.

Halftone Printing

Halftone prints are single or multiple colors in which gradients are printed. These tones can range from solid spots to halftones of the same color. This screen printing method is excellent when you want to achieve the look of multi-color printing without actually doing it. This screen printing method emphasizes the use of shading with tiny dots, pictures can be printed using halftone screen printing and only use one single color to do so.

For example, if you want to get a pink radiant color on your white t-shirt, you can print red on a white shirt and include a 50% gradient. The 50% gradient will mix with the white to give it a pink appearance, all using only one screen and one color. It improves the graphics quality and produces a softer feeling print when printed directly onto the garment. Check “How To Get Started Screen Printing with Halftones”.

Grayscale Printing

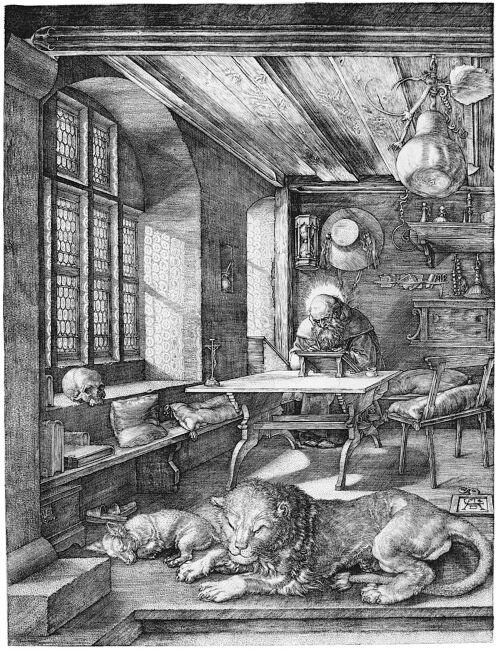

Greyscale printing is a great way to print full-color images as one-color grayscales or halftones. Full-color photographs can be printed as a one-color halftone. Full-color drawings containing a complete range of different colors may also be produced employing a one-color halftone.

Typically it’s done in black ink on a light garment, but technically speaking, it can be done in any color ink as desired. The resolution will depend on the lines per inch used in the dot pattern.

The more dots a halftone has, the more detailed the print will look. It is a great cost-effective screen printing technique to print black and white photographs on garments. Watch “Convert a full color image to grayscale for screen printing using halftones”.

HOW IS HALFTONE PRINTING DIFFERENT THAN A GRAYSCALE?

Halftone printing is different than grayscale printing for several reasons. The first is the fact that halftone printing involves using one color to create various shades and portray the desired image as a result. Grayscale printing, on the other hand, is the specific use of gray shades from black and white.

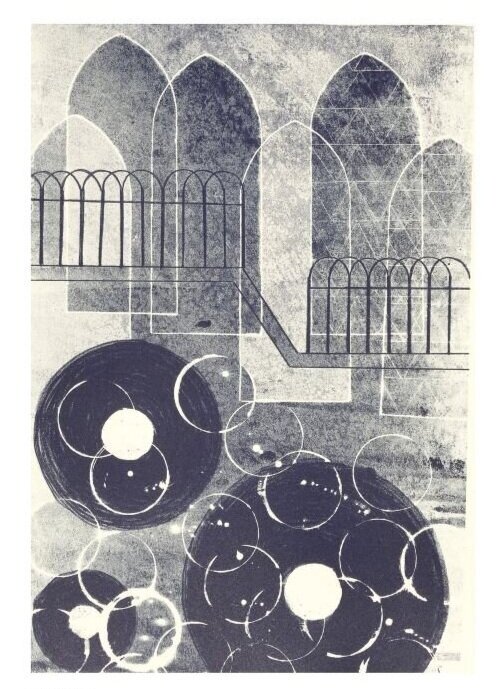

Duotone Printing

Duotone printing, also known as multitone printing, is the combination of two halftones for the same image printed with two colors. First, a black halftone is printed on white tees, and then a second halftone will be printed with color ink.

The color halftone combines with the black halftone to produce a duotone color hue. It gives a retro and cooling effect to the prints on light-color garments and gives a full-color print appearance but at a much less expensive rate. It also produces a softer feel print when printed onto the garment.

This process requires that the press be set up with special inks, usually PANTONE-designated colors, instead of the standard CMYK inks used for process color printing. Check out “Creating and Separating Duotone Images”.

CMYK Printing

CMYK is the oldest, color reproduction, print method. Using cyan, magenta, yellow and black ink, screen printers can print designs on white or light-colored garments. For users skilled in CMYK file preparation, Photoshop, and screen creation, this is still a viable print process for light-colored garments.

CMYK printing is the most complex of all screen printing techniques and should be done on an automatic press. It can be done manually, but for optimum results, you need an automatic t-shirt press.

The printing process combines the above four colors to recreate the original image’s full tonal and color range. Moreover, it is an expensive process. Additionally, CMYK is implemented less because simulated printing is more dominant. Watch “How To Screen Print T-Shirts in CMYK”.

Simulated Process Printing

A simulated printing process is a method used to reproduce almost any image on the market. It does so by overlapping and blending colors in a method similar to CMYK through using halftones and spot colors and/or PMS colors. Essentially, it's a way of taking an image that historically would have been printed via CMYK but instead uses more opaque ink to create a more stable color and production-friendly ink that can print almost any design for any garment.

Moreover, it is most often the process used to print complex images on black-colored garments. Designs that are too difficult to separate in a vector program, raster images, photographs, complex tonal illustrations, are all doable with Simulated Process. Watch “How to Screen Print: Simulated Process”.

Learn more about the different screen printing methods “CMYK vs. Spot Color vs. Simulated Process Printing”.

Author: Irene Floridia - Content Creator

Share This Article:

Follow us on Instagram and Facebook!

For FAQ, check out our site!

For any inquiries, send us a message!

OR

send us an e-mail at quotes@familyindustriesla.com

Our showroom at 2755 Fruitdale Street, Los Angeles, CA 90039 is open by appointment only from 10 am - 4 pm Monday through Friday.